- Catalog

- Industries

- Products

-

- Seal-Connect®

- Electrical Connectors

- Single-Pin Connectors

- Multi-Pin Connectors

- Coax Connectors

- KTK-Style Connectors

- Rotatable Connectors

- Contact Blocks

- Boot Kits

- Perforating Gun Tool Connectors

- Wet Stab Connectors

- Fiber Optic Connectors

- Connectors

- Adapters

- Bulkhead Feedthrough

- Dust Caps

- Fiber Optic Cable, Patch Cord, & Pigtail Assemblies

- Fiber Optic Extreme

- VIEW ALL Seal-Connect®

- Sealing Solutions

- Structural Components

- Engineering Components

- Chemraz®

- Elastomers

- Advanced Engineering Thermoplastics

- Thermoplastic Composites

- Seal-Connect®

-

- Resources

- Company View Cart

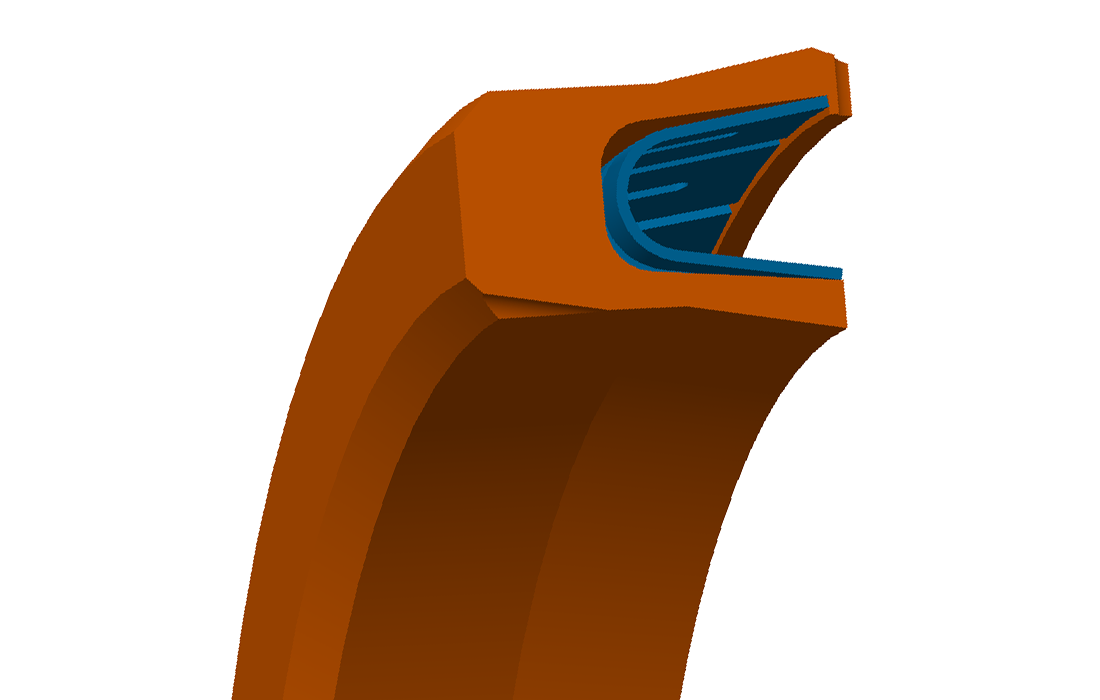

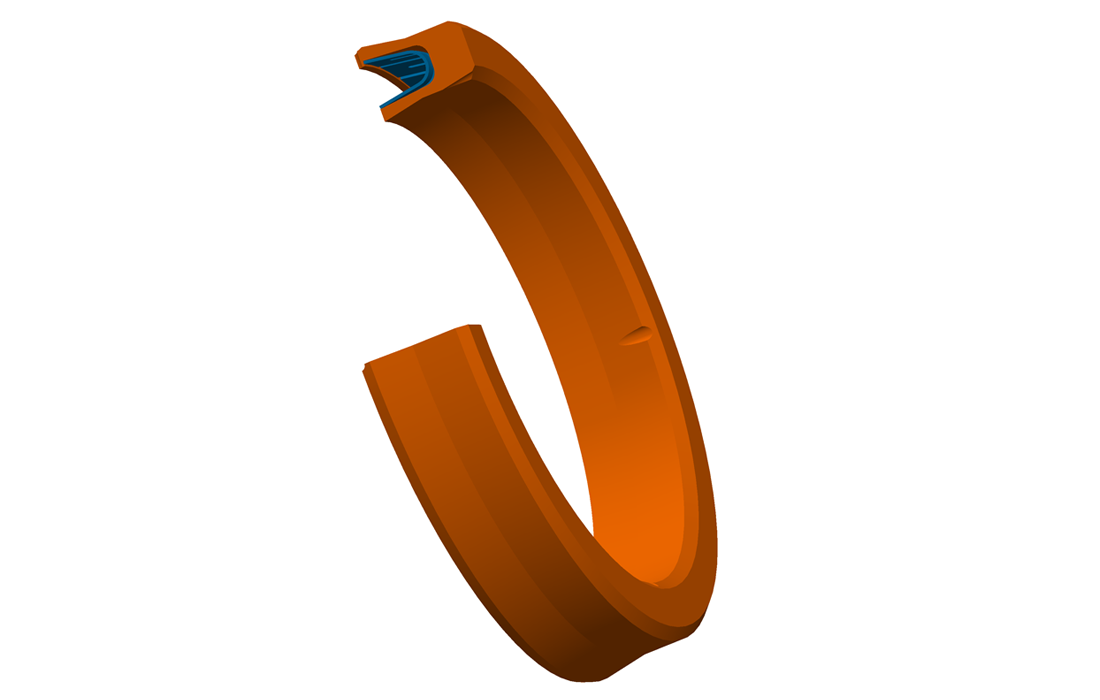

Scraper Lip

The MSE® seal’s superior designed dual-lip body offers improved sealing performance in virtually unlimited media service and the widest temperature range. Finger Seal MSE® seals use a cantilever-type stainless steel spring to act as an energizer during low pressure situations. The spring compensates for seal wear in dynamic applications as well as overcoming the nonresilient nature of PTFE materials.

The scraper lip design is best suited for nonlubricated applications where abrasive media are present and space is limited. The scraper lip keeps abrasive media from getting between the seal and the hardware, thus decreasing abrasion. Available in rod and piston designs. Applicable to both static and dynamic applications.

Features & Benefits

- Low friction

- Precise and uniform movement without stick/slip

- Low power absorption and torque requirements

- Friction can be adjusted and controlled

- Can run dry or lubricated giving a long service life Able to withstand corrosive environments

- Virtually unlimited media service with one seal

- Will not contaminate sensitive media Wide temperature performance envelope

- Cryogenic to 550°F (288°C), providing excellent performance at extreme temperatures Operates effectively at pressures from vacuum to 19,000 psi (1,310 bar) and up to 30,000 psi (2,068 bar) with custom designed anti-extrusion ring.*

Applications

| Aerospace – Aircraft engines, APUs (auxiliary power units), Brakes, Fuel controls, pumps, valves, Gearboxes, Hydraulic systems, Oxygen systems, Scrapers across various platforms, Utility and landing gear actuation systemsEnergy – Blow-out preventor, Chemical mixers, Compressors, Cryogenic systems, Downhole tools, Drilling and completion tools, Fluid dispensing systems, Pipeline equipment, Valve stems Semiconductor Industrial |

Temperature Range

Maximum Pressure

Add this to your cart and we can discuss your requirements.